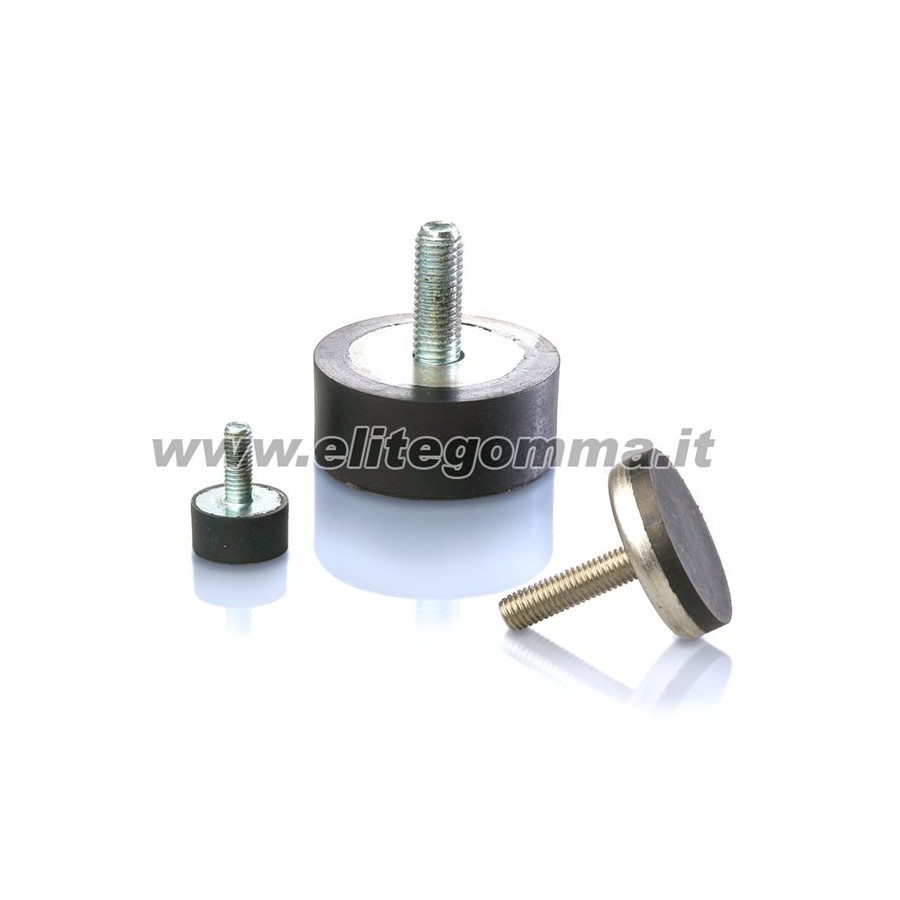

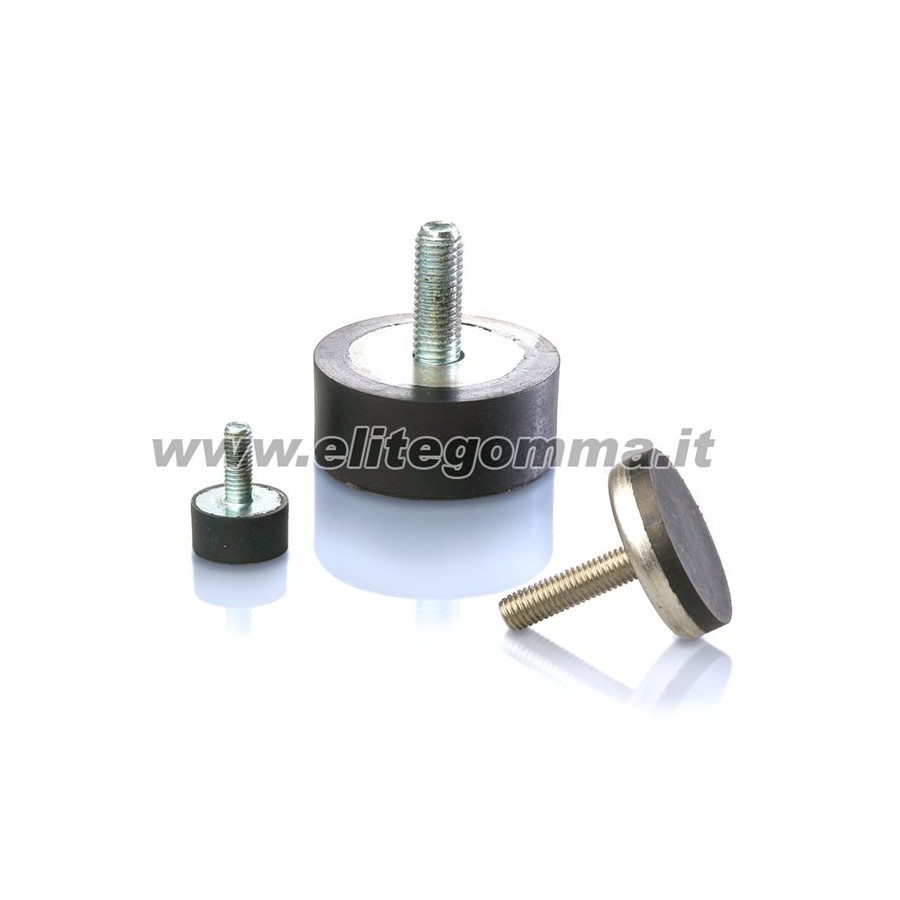

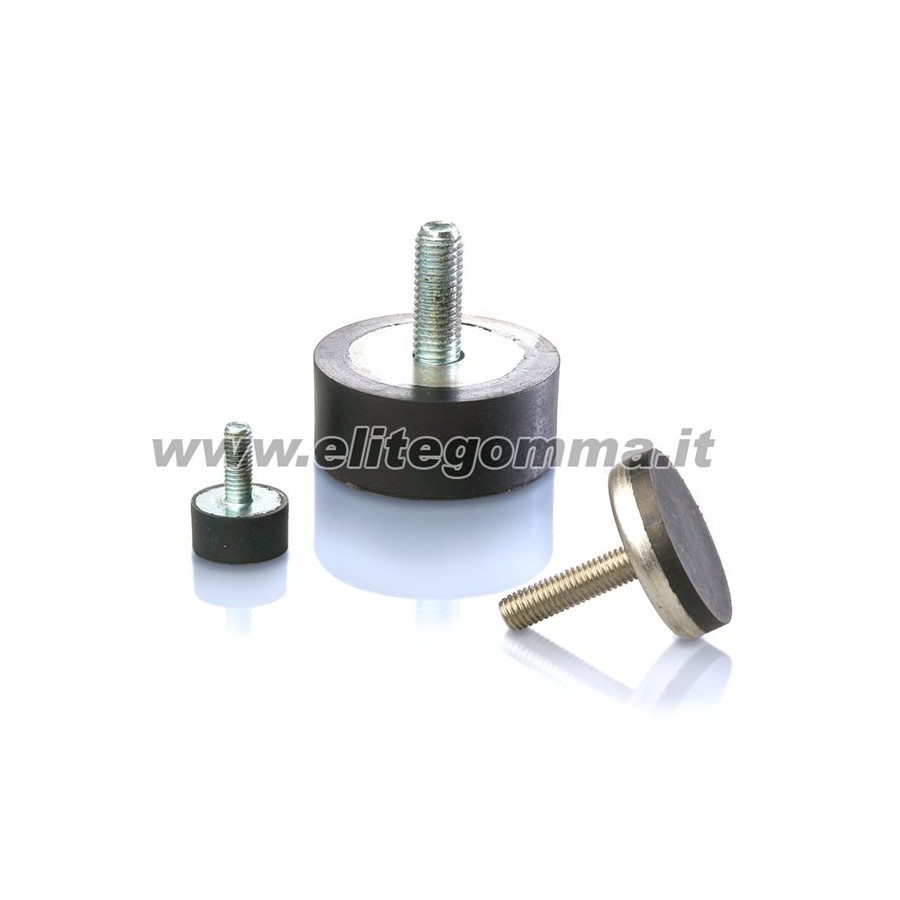

The cylindrical bumpers are used in a wide range of industrial and commercial applications to absorb impacts, vibrations and mechanical shocks. These components are commonly used in the electronics, automotive industry, appliance, furniture and many others sectors. In summary, the cylindrical paradolling feet offer an effective solution to protect surfaces, reduce noise and prolong the duration of objects and structures in multiple operating contexts.

Quality policies

Quality policies

Quality products and ISO 9001:2015 certification

Quick availability

Quick availability

High rotation product in stock

Multi-language support

Multi-language support

We respond in Italian, English and German

The cylindrical bumper feet represent a reliable and versatile solution to guarantee a stable base on non -flat surfaces or in the presence of vibrant machinery in a wide range of industrial sectors. Their application is fundamental in contexts where it is essential to ensure correct structure with the land for the optimal operation of the equipment.

Thanks to their cylindrical shape and the flexibility of the rubber, the cylindrical bumper feet are effectively adapted to the variations of the soil or the irregularities of the support surfaces. The main feature of the rubber used in these feet is elasticity, which allows them to effectively absorb the vibrations generated by the machinery in operation or to compensate for the roughness of the support surface.

The mixes recommended for these cylindrical bumper feet include a wide range of elastomeric materials, including SBR, NBR, Neoprene, Epdm and Veton. Each compound offers specific properties of chemical resistance, abrasion resistance, durability and elastic behavior, allowing to adapt your feet to the specific needs of the application.

In addition, we have developed specially designed products for the medical sector, where very high quality standards are required. Thanks to our experience and technical competence, we are able to offer solutions that meet the most rigorous requirements in terms of safety and quality.

Our team of specialized technicians is available to collaborate with customers and develop tailor -made solutions that meet the specific needs of the application. We are ready to provide the necessary support to ensure the success of your project, whether it is to adapt the characteristics of the material or to design particular shapes to obtain maximum performance and reliability.

| Codice | Ø A [mm] | Altezza B [mm] | Vite C [mm] | Ø Filetto F [mm] | Carico Max [Kg] |

|---|---|---|---|---|---|

| PIE 20/10 | 20 | 10 | 16 | 6MA maschio | 35 |

| PIE 25/7 | 25 | 7 | 23 | 8MA maschio | 60 |

| PIE 25/18RM6 | 25 | 18 | 17 | 6MA maschio | 70 |

| PIE 37/35RM8 | 37 | 35 | 23 | 8MA maschio | 80 |

| PIE 40/15RM10 | 40 | 15 | 23 | 10MA maschio | 110 |

| PIE 40/15RM8X22 | 40 | 15 | 22 | 8MA maschio | 110 |

| PIE 40/25RM8 | 40 | 25 | 23 | 8MA maschio | 90 |

| PIE 40/30RF8 | 40 | 30 | 8MA Femmina | 120 | |

| PIE 40/30RM8 | 40 | 30 | 23 | 8MA maschio | 120 |

| PIE 40/30RM10 | 40 | 30 | 23 | 10MA maschio | 120 |

| PIE 40/40RF8 | 40 | 40 | 8MA femmina | 130 | |

| PIE 40/40RF10 | 40 | 40 | 10MA femmina | 130 | |

| PIE 40/40RM8 | 40 | 40 | 23 | 8MA maschio | 130 |

| PIE 40/40RM10 | 40 | 40 | 23 | 10MA maschio | 130 |

| PIE 48X14RM10 | 48 | 14 | 27 | 10MA maschio | 140 |

| PIE 50/20RM10 | 50 | 20 | 48 | 10MA maschio | 160 |

| PIE 110/30RM14 | 110 | 30 | 70 | 14MA maschio | 200 |

Call Our Store

rty

ewr