Our antivibrants are successfully employed in high stress sectors, such as compressors, brushcutters and carrier, demonstrating their reliability and resistance even in extreme operating conditions.

Quality policies

Quality policies

Quality products and ISO 9001:2015 certification

Quick availability

Quick availability

High rotation product in stock

Multi-language support

Multi-language support

We respond in Italian, English and German

The exceptional quality of the antivibrants produced by Elte Gomma is the result of a long path of experience accumulated in the sector and of a constant commitment to pursue continuous improvements. Our company stands out for the rigor and attention with which it selects and implements the best practices in the production process, thus guaranteeing the high quality standard of our products.

Contrary to many other anti-vibrant on the market, none of our products come from external productions of questionable quality. We invest significant resources in research and development, as well as in quality control, to ensure that every anti -vibration that comes out of our production lines satisfies the highest standards of performance and reliability.

Furthermore, thanks to the industrialization achieved, Elte Gomma is able to maintain an excellent quality-price ratio, ensuring that our customers receive a very high quality product without having to compromise their budget.

Our antivibrants have been successfully employed for many years in high stress sectors, such as compressors, brushcutters and carrier, where the resistance and reliability of the components are essential to guarantee optimal and lasting performance.

We are always open to collaboration with our customers to study personalized solutions that meet their specific needs. Our approach includes a careful theoretical study to accurately determine the final values of the parameters, such as FP, K, D and H, in order to identify the best anti -vibration to be used in any situation.

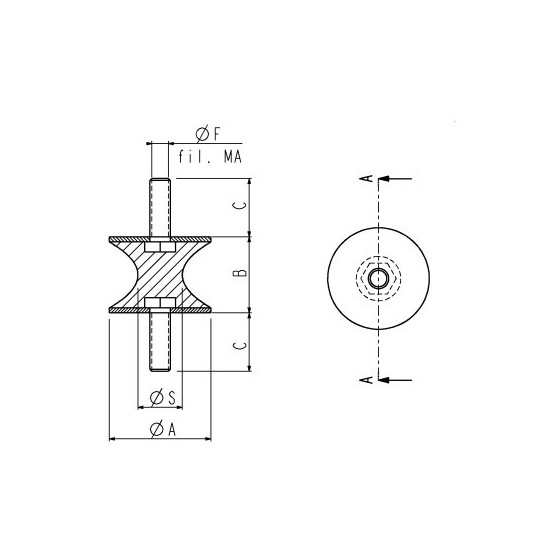

The technical characteristics of our antivibrants have been carefully designed to guarantee optimal and lasting performance. The rubber-metal attack is designed to bear the same traction of the rubber body, while the special compound in NBR/SBR ensures a large cycle of hysteresis for better dissipation of the vibrations. Our rigorous control of vulcanization guarantees the absolute absence of air bubbles inside the rubber body, while all inserts are made of high quality steel, with the possibility of requesting stainless steel inserts on a specific request. The metal parts are continuously and robustly united, ensuring a reliable connection, while galvanization ensures lasting protection against corrosion.

We offer a range of mixes recommended for our articles, including SBR (Stirolic rubber), NBR (nitrilic rubber), VMQ (siliconic rubber) and Viton (fluoroelastomer), with the possibility of personalizing the choice according to the specific needs of the application.

| Codice | Ø ( A ) [mm] | Altezza ( B) [mm] | Conca ( S ) [mm] | Vite ( C ) [mm] | Serie | Ø Filetto ( F ) [mm] | Carico Max [Kg] | Carico per flessione [Kg] |

|---|---|---|---|---|---|---|---|---|

| ATS252010MM660 | 25 | 20 | 10 | 14 | MM | M6 | 50 | 3 |

| ATS252010MF660 | 25 | 20 | 10 | 14 | MF | M6 | 50 | 3 |

| ATS252010FF660 | 25 | 20 | 10 | 14 | FF | M6 | 50 | 3 |

| ATS403019MM860 | 40 | 30 | 19 | 18 | MM | M8 | 80 | 6 |

| ATS403019MF860 | 40 | 30 | 19 | 18 | MF | M8 | 80 | 6 |

| ATS403019FF860 | 40 | 30 | 19 | 18 | FF | M8 | 80 | 6 |

| ATS403027MM860 | 40 | 30 | 27 | 18 | MM | M8 | 100 | 8 |

| ATS403027MF860 | 40 | 30 | 27 | 18 | MF | M8 | 100 | 8 |

| ATS403027FF860 | 40 | 30 | 27 | 18 | FF | M8 | 100 | 8 |

Call Our Store

rty

ewr